Manufacturing Capabilities Behind Custom NasalStrip Projects

The growing demand for personalized healthcare solutions has positioned custom nasal strips as a significant market opportunity for manufacturers worldwide. These specialized breathing aids require sophisticated production capabilities that combine medical-grade materials with precision manufacturing processes. Understanding the manufacturing landscape behind custom nasal strips reveals the complexity and innovation driving this essential healthcare product category.

Modern manufacturing facilities dedicated to producing custom nasal strips must meet stringent regulatory requirements while maintaining cost-effective production scales. The integration of advanced adhesive technologies with breathable materials creates products that deliver both comfort and functionality. These manufacturing capabilities extend beyond basic production to encompass research and development, quality control, and specialized packaging solutions tailored to individual client specifications.

Advanced Material Selection and Processing

Medical-Grade Adhesive Development

The foundation of effective custom nasal strips lies in proprietary adhesive formulations that balance holding power with skin compatibility. Manufacturing facilities invest heavily in adhesive research laboratories where chemists develop hypoallergenic compounds that maintain their grip throughout extended wear periods. These adhesives must undergo rigorous biocompatibility testing to ensure they meet medical device standards while providing the necessary tensile strength for nasal dilation applications.

Processing these specialized adhesives requires controlled environment chambers where temperature and humidity levels remain constant throughout production cycles. The coating application process utilizes precision machinery that ensures uniform adhesive distribution across the substrate material. Quality control measures include continuous monitoring of adhesive thickness, tack levels, and curing parameters to maintain consistent performance characteristics across production batches.

Non-Woven Substrate Manufacturing

The substrate material for custom nasal strips demands specific fiber compositions that provide flexibility while maintaining structural integrity. Manufacturing facilities employ specialized spunbond or meltblown processes to create non-woven fabrics with controlled porosity and tensile properties. These materials must demonstrate excellent breathability characteristics while resisting deformation under typical usage conditions.

Advanced manufacturing lines incorporate inline testing systems that continuously evaluate substrate properties including air permeability, thickness uniformity, and tensile strength. The material selection process considers factors such as skin compatibility, moisture management, and long-term stability under various environmental conditions. Custom formulations often require proprietary fiber blends that optimize performance for specific customer applications or demographic requirements.

Precision Manufacturing Processes

Die-Cutting and Shaping Technology

The transformation of raw materials into finished custom nasal strips requires sophisticated die-cutting equipment capable of producing consistent shapes with tight dimensional tolerances. Manufacturing facilities utilize rotary die-cutting systems that operate at high speeds while maintaining precision cuts across multiple layers simultaneously. These systems incorporate vision inspection technology that automatically detects and rejects products that fall outside specified dimensional parameters.

Custom tooling development represents a critical capability for manufacturers serving diverse client requirements. The ability to rapidly prototype and produce specialized cutting dies enables quick turnaround times for new product configurations. Advanced laser cutting technologies complement traditional die-cutting methods, particularly for small batch custom orders or complex geometric shapes that would be cost-prohibitive using conventional tooling approaches.

Automated Assembly and Packaging Lines

Modern manufacturing facilities integrate fully automated assembly lines that combine multiple components into finished custom nasal strips while maintaining sterile production environments. These systems incorporate servo-controlled placement mechanisms that ensure precise component alignment and consistent adhesive bond formation. Automated inspection stations utilize machine vision systems to verify product completeness and detect cosmetic defects before packaging.

Packaging capabilities extend to individual pouching, blister pack formation, and bulk packaging options depending on customer requirements. Serialization and traceability systems enable complete lot tracking from raw materials through finished product distribution. Climate-controlled packaging areas maintain optimal conditions for heat-sealing operations and prevent moisture infiltration that could compromise product integrity during storage and transportation.

Quality Assurance and Regulatory Compliance

Comprehensive Testing Protocols

Manufacturing facilities dedicated to custom nasal strips implement extensive testing protocols that evaluate both individual component properties and finished product performance. Adhesion testing equipment measures peel strength, shear resistance, and tack properties under standardized conditions that simulate actual usage scenarios. Biocompatibility testing follows ISO 10993 standards to ensure skin safety and minimize allergic reaction risks.

Environmental stress testing subjects custom nasal strips to accelerated aging conditions that predict long-term stability and performance degradation patterns. These tests include exposure to elevated temperatures, humidity cycling, and UV radiation to validate shelf-life claims and storage recommendations. Microbial testing protocols ensure sterility maintenance throughout the manufacturing and packaging processes.

Regulatory Documentation and Certification

Successful manufacturing operations maintain comprehensive documentation systems that support regulatory submissions and certification requirements across multiple international markets. Quality management systems aligned with ISO 13485 standards provide the framework for consistent process control and continuous improvement initiatives. Design control procedures ensure that custom nasal strips meet specified performance criteria and regulatory requirements before commercial release.

Technical file preparation capabilities enable manufacturers to support customer regulatory submissions in various jurisdictions including FDA 510k clearances, CE marking requirements, and other international medical device certifications. Risk management documentation following ISO 14971 guidelines demonstrates systematic evaluation of potential hazards and implementation of appropriate risk mitigation measures.

Customization and Innovation Capabilities

Design Flexibility and Rapid Prototyping

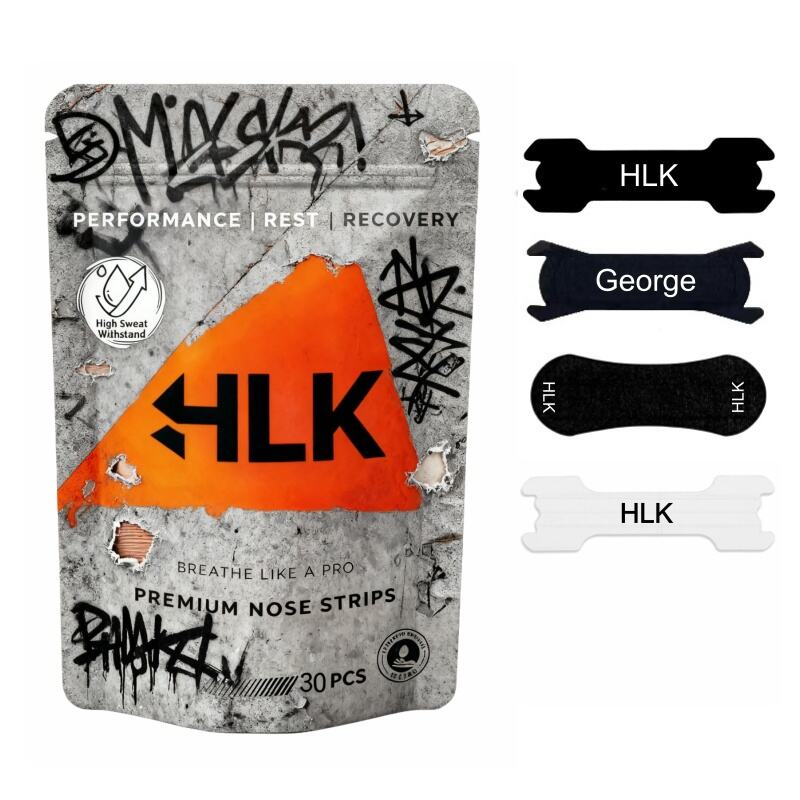

Leading manufacturers offer extensive customization options that allow clients to specify unique product characteristics including size variations, adhesive strength levels, and aesthetic elements such as color and printing. Computer-aided design capabilities enable rapid visualization of custom nasal strips configurations and facilitate customer approval processes before tooling commitments. Rapid prototyping services utilize 3D printing and small-batch production methods to validate designs and conduct preliminary testing.

Material experimentation programs explore novel substrate compositions and adhesive formulations that address specific performance requirements or target demographic preferences. These innovation initiatives often result in proprietary material combinations that provide competitive advantages for custom applications. Collaborative development programs engage customers in co-creation processes that leverage manufacturing expertise with market insights.

Scalable Production Planning

Effective manufacturing operations demonstrate flexibility in production scheduling and volume management to accommodate varying customer demand patterns. Modular production line designs enable rapid changeovers between different custom nasal strips configurations while minimizing setup times and material waste. Inventory management systems balance raw material availability with production capacity to ensure consistent delivery performance.

Capacity planning tools utilize historical demand data and market forecasts to optimize equipment utilization and workforce allocation. Strategic partnerships with material suppliers ensure reliable access to specialized components while maintaining cost competitiveness. Manufacturing execution systems provide real-time visibility into production status and enable proactive management of potential delays or quality issues.

Supply Chain Integration and Logistics

Supplier Qualification and Management

The manufacture of custom nasal strips requires sophisticated supplier networks that provide specialized materials and components meeting medical device standards. Supplier qualification programs evaluate technical capabilities, quality systems, and regulatory compliance status to ensure consistent material quality and supply continuity. Strategic sourcing initiatives balance cost optimization with performance requirements and supply chain risk mitigation.

Vendor audit programs include on-site assessments of manufacturing facilities, quality control procedures, and documentation systems. Long-term partnership agreements with key suppliers enable collaborative development of improved materials and cost reduction initiatives. Contingency planning identifies alternative suppliers and maintains qualified backup sources for critical materials to prevent production disruptions.

Global Distribution Networks

Manufacturing facilities serving international markets implement sophisticated logistics systems that manage complex shipping requirements and regulatory documentation across multiple jurisdictions. Temperature-controlled storage and transportation capabilities preserve product integrity during extended distribution cycles. Customs clearance expertise ensures efficient border crossings and minimizes delays that could impact customer delivery schedules.

Regional distribution centers enable local inventory management and rapid response to customer orders while reducing transportation costs and delivery times. Track and trace systems provide complete visibility into shipment status and enable proactive communication with customers regarding delivery schedules. Returns processing capabilities handle product recalls or quality issues efficiently while maintaining regulatory compliance and customer satisfaction.

Technology Integration and Industry 4.0

Smart Manufacturing Systems

Advanced manufacturing facilities incorporate Industry 4.0 technologies that enhance production efficiency and quality control capabilities for custom nasal strips production. Internet of Things sensors monitor equipment performance, environmental conditions, and process parameters in real-time to enable predictive maintenance and optimize production settings. Machine learning algorithms analyze historical production data to identify optimization opportunities and predict quality issues before they occur.

Digital twin technologies create virtual representations of manufacturing processes that enable simulation and optimization without disrupting actual production operations. These systems facilitate rapid evaluation of process changes and support continuous improvement initiatives. Cloud-based data analytics platforms aggregate information from multiple production lines and facilities to provide comprehensive performance insights and benchmarking capabilities.

Cybersecurity and Data Protection

Modern manufacturing operations implement robust cybersecurity measures to protect proprietary formulations, customer information, and operational data from unauthorized access or theft. Network segmentation isolates critical production systems from external connections while enabling necessary data sharing for supply chain coordination and customer communication. Regular security assessments identify vulnerabilities and ensure compliance with industry standards and customer requirements.

Data backup and recovery systems ensure business continuity in the event of system failures or cyber incidents. Employee training programs maintain awareness of cybersecurity best practices and promote responsible handling of sensitive information. Incident response procedures enable rapid containment and remediation of potential security breaches while minimizing operational disruptions and customer impact.

FAQ

What manufacturing capabilities are essential for producing high-quality custom nasal strips

Essential manufacturing capabilities include precision die-cutting equipment, controlled environment adhesive coating systems, automated assembly lines with vision inspection, and comprehensive quality control laboratories. Facilities must maintain clean room environments, implement robust supply chain management, and demonstrate regulatory compliance across multiple international markets. Advanced material processing capabilities and rapid prototyping services enable customization while maintaining production efficiency.

How do manufacturers ensure consistent quality across different custom nasal strips specifications

Quality consistency relies on standardized process controls, automated monitoring systems, and comprehensive testing protocols that evaluate both raw materials and finished products. Statistical process control methods track key performance indicators and trigger corrective actions when parameters drift outside acceptable ranges. Supplier qualification programs ensure material consistency while change control procedures prevent unauthorized modifications that could impact product quality.

What role does regulatory compliance play in custom nasal strips manufacturing

Regulatory compliance forms the foundation of legitimate custom nasal strips manufacturing, requiring adherence to medical device standards including ISO 13485 quality management systems and biocompatibility testing protocols. Manufacturers must maintain detailed documentation supporting product safety and efficacy claims while enabling customer regulatory submissions. Compliance capabilities directly impact market access and determine the ability to serve customers in regulated healthcare markets.

How do manufacturing facilities accommodate varying volume requirements for custom nasal strips orders

Flexible manufacturing systems utilize modular production line designs that enable rapid changeovers between different product configurations while optimizing equipment utilization. Scalable capacity planning incorporates demand forecasting and inventory management to balance production efficiency with customer delivery requirements. Strategic partnerships and contract manufacturing relationships provide additional capacity options for large orders while maintaining cost competitiveness across varying volume levels.