Using Customer Feedback to Improve NasalStrip Design

Customer feedback serves as the cornerstone for developing effective nasal strips that truly address sleep-related breathing challenges. When manufacturers actively listen to user experiences, they can identify specific design flaws, comfort issues, and performance gaps that may not be apparent during initial product development. This iterative approach to product improvement ensures that nasal strips evolve to meet real-world needs rather than theoretical expectations. By systematically collecting and analyzing customer input, companies can transform basic adhesive strips into sophisticated breathing aids that deliver measurable results for snoring reduction and improved sleep quality.

Understanding Customer Pain Points Through Direct Feedback

Identifying Common Adhesion Problems

Customer reviews frequently highlight adhesion issues as a primary concern with traditional nasal strips. Users report that strips lose their grip during sleep, particularly when they sweat or move frequently throughout the night. This feedback has driven manufacturers to explore advanced adhesive technologies that maintain their hold without causing skin irritation upon removal. The challenge lies in balancing adhesive strength with gentle removal properties, ensuring that nasal strips stay in place for eight hours while allowing painless removal in the morning.

Seasonal variations also impact adhesion effectiveness, with customers noting that nasal strips perform differently in humid versus dry environments. Winter heating systems can dry out nasal passages and skin, affecting how well strips adhere, while summer humidity can cause premature loosening. These insights have led to the development of climate-adaptive adhesives that adjust their bonding strength based on environmental conditions.

Addressing Comfort and Skin Sensitivity Concerns

Sensitive skin reactions represent another significant area where customer feedback drives product evolution. Users with allergies or sensitive skin often experience redness, itching, or even mild rashes from prolonged contact with certain adhesive materials. This feedback has prompted manufacturers to investigate hypoallergenic materials and develop nasal strips with skin-friendly formulations that maintain effectiveness without compromising comfort.

The shape and flexibility of nasal strips also impact user comfort significantly. Customers frequently mention that rigid strips feel unnatural and can cause pressure points on the nose bridge. This input has led to innovations in strip design, including curved profiles that better match natural nose contours and flexible materials that move with facial expressions during sleep.

Measuring Effectiveness Through User Experience Data

Sleep Quality Improvement Metrics

Customer feedback provides invaluable data on how effectively nasal strips improve actual sleep quality. Users often track their sleep patterns using wearable devices, providing objective measurements of sleep duration, wake frequency, and overall sleep efficiency. This data reveals that while nasal strips may successfully reduce snoring volume, their impact on sleep quality varies significantly based on individual anatomy and breathing patterns.

Customers also report subjective improvements in morning alertness and daytime energy levels when using high-quality nasal strips consistently. These testimonials help manufacturers understand the broader health benefits beyond simple snoring reduction. Partner feedback is equally valuable, as bed partners can observe snoring reduction and sleep movement patterns that users themselves cannot detect.

Long-term Usage Patterns and Compliance

Sustained use data from customer feedback reveals important insights about product design effectiveness. Users who continue purchasing nasal strips month after month provide evidence of genuine product value, while high abandonment rates signal potential design flaws or unmet expectations. Feedback analysis shows that users are more likely to continue using nasal strips that remain comfortable throughout the night and show consistent performance over time.

Customer reviews also highlight the importance of packaging design and strip removal ease. Users prefer packaging that allows easy one-handed strip removal without damaging the adhesive surface. These practical considerations significantly impact user satisfaction and long-term product adoption rates.

Innovative Design Solutions Based on Customer Input

Advanced Materials and Construction Techniques

Customer feedback about traditional adhesive strips has sparked innovation in alternative attachment methods. Users seeking more comfortable and reusable options have driven the development of nasal strips that use magnetic technology instead of adhesives. These magnetic alternatives address many common complaints about skin irritation and adhesive residue while providing consistent positioning throughout the night.

Breathable materials have become another focus area based on customer requests for strips that allow natural skin ventilation. Users reported feeling claustrophobic or experiencing increased skin moisture with non-breathable strips, leading manufacturers to incorporate perforated designs and moisture-wicking materials that maintain adhesion while allowing air circulation.

Customization Options for Individual Needs

Diverse customer feedback has highlighted the need for size variations and adjustable nasal strips. Users with different nose shapes and sizes require different strip dimensions for optimal effectiveness. This input has led to the development of strip families that include small, medium, and large sizes, as well as strips with adjustable tension settings that users can modify based on their specific breathing needs.

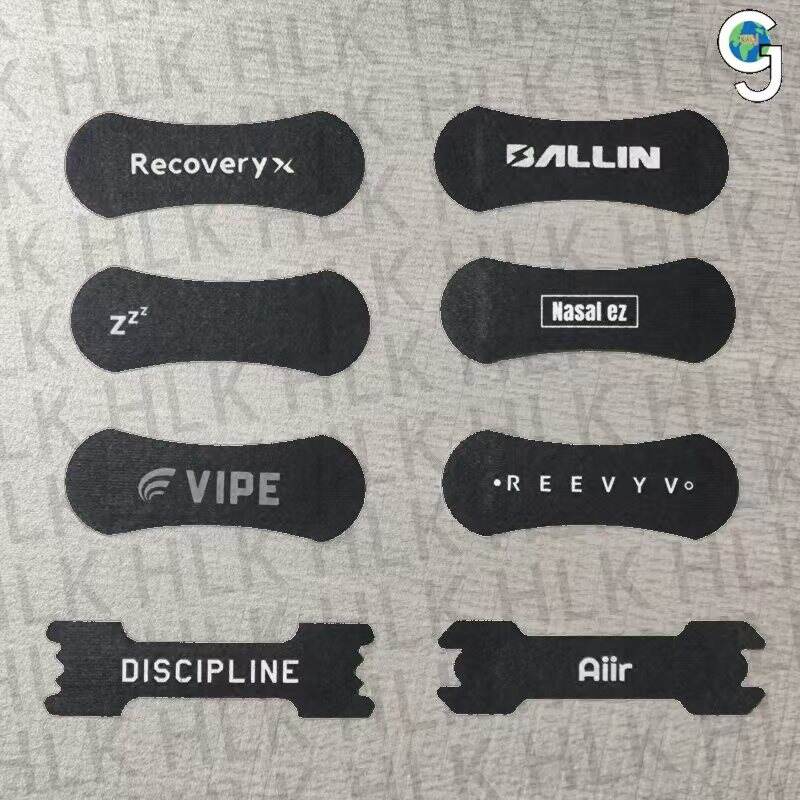

Color options and discrete designs have also emerged from customer requests, particularly from users who are self-conscious about wearing visible nasal strips. Clear or skin-toned strips address aesthetic concerns while maintaining full functionality, broadening the user base to include individuals who might otherwise avoid nasal strips due to appearance considerations.

Testing and Validation Through Customer Trials

Beta Testing Programs with Real Users

Structured beta testing programs allow manufacturers to collect detailed feedback before full product launches. These programs typically involve sending prototype nasal strips to existing customers who provide comprehensive usage reports over several weeks. Participants track sleep quality, comfort levels, adhesion effectiveness, and any side effects, generating rich datasets that inform final design decisions.

Beta testers often identify edge cases and unusual usage scenarios that laboratory testing might miss. For example, customers who sleep on their stomachs, use CPAP machines, or have facial hair provide unique insights about how nasal strips perform under specific conditions. This real-world testing ensures that final products work effectively across diverse user populations.

Continuous Improvement Cycles

Customer feedback creates ongoing improvement cycles that keep nasal strips evolving with user needs. Manufacturers who establish regular feedback collection systems can identify emerging trends and address new challenges as they arise. This might include adapting to changes in bedroom environments, responding to new health awareness trends, or incorporating feedback from aging customer bases whose needs change over time.

Social media and online review platforms provide immediate feedback channels that allow rapid response to customer concerns. Companies that monitor these channels actively can quickly identify and address widespread issues, preventing negative experiences from affecting larger customer populations. This responsive approach builds customer loyalty and maintains product quality standards.

Manufacturing and Quality Control Improvements

Production Process Refinements

Customer feedback about inconsistent nasal strips performance often traces back to manufacturing variations. Users who receive strips with varying adhesive strength or material flexibility help manufacturers identify quality control gaps in their production processes. This feedback drives improvements in material sourcing, production line monitoring, and final product testing protocols.

Packaging feedback also influences manufacturing decisions, particularly regarding strip storage conditions and shelf life. Customers who report reduced effectiveness over time help manufacturers understand how environmental factors during shipping and storage affect product quality. These insights lead to improved packaging materials and storage recommendations that maintain strip effectiveness until use.

Supply Chain and Distribution Optimization

Customer experiences with product availability and ordering processes provide valuable feedback for supply chain management. Users who struggle to find their preferred nasal strips or experience shipping delays help manufacturers identify distribution gaps and optimize their retail partnerships. This feedback ensures that effective products remain accessible to users who depend on them for consistent sleep quality.

International customers provide additional insights about how nasal strips perform in different climates and cultural contexts. This global feedback helps manufacturers understand whether their products require regional adaptations or if universal designs can meet diverse needs effectively.

Future Directions Based on Customer Insights

Technology Integration Opportunities

Customer feedback increasingly suggests interest in smart nasal strips that can provide usage data and effectiveness metrics. Users want to understand how their breathing patterns change with strip use and track their progress over time. This demand drives research into strips with embedded sensors that can monitor breathing rates, sleep position, and other relevant metrics without compromising comfort or effectiveness.

Mobile app integration represents another area where customer feedback indicates strong interest. Users want to log their experiences, track sleep quality improvements, and receive personalized recommendations for optimal strip usage. These digital tools can also facilitate easier feedback submission, creating more robust data collection systems for ongoing product development.

Sustainability and Environmental Considerations

Environmentally conscious customers increasingly request sustainable nasal strips options, including biodegradable materials and reduced packaging waste. This feedback drives research into eco-friendly adhesives and backing materials that maintain effectiveness while reducing environmental impact. Reusable magnetic nasal strips address some of these concerns by eliminating single-use adhesive waste.

Customers also express interest in refillable or subscription-based models that reduce packaging and shipping frequency. These distribution innovations can improve customer convenience while addressing environmental concerns, creating win-win solutions that benefit both users and manufacturers.

FAQ

How do manufacturers collect customer feedback for nasal strips improvement

Manufacturers collect customer feedback through multiple channels including online surveys, product reviews, customer service interactions, and social media monitoring. Many companies also establish formal beta testing programs where customers try new designs and provide detailed usage reports. Direct customer interviews and focus groups provide deeper insights into user experiences and preferences that help guide product development decisions.

What are the most common customer complaints about traditional nasal strips

The most frequent customer complaints involve adhesion problems, particularly strips falling off during sleep or losing effectiveness in humid conditions. Skin sensitivity and irritation from adhesives represent another major concern, along with comfort issues from rigid strip designs. Customers also commonly report inconsistent performance between different strip batches and difficulty removing strips without leaving residue or causing skin discomfort.

How long does it typically take to implement customer feedback into nasal strips design changes

Simple design modifications based on customer feedback can be implemented within a few months, while more complex material or manufacturing changes may take six to twelve months to complete. Major innovations like magnetic attachment systems or smart sensor integration can require one to two years of development and testing. The timeline depends on the complexity of the requested changes and the need for safety testing and regulatory approvals.

Do customer preferences for nasal strips vary by geographic region or demographics

Yes, customer preferences show significant variation based on climate, cultural factors, and demographic characteristics. Users in humid climates prioritize sweat-resistant adhesives, while those in dry environments may prefer gentler adhesion. Age-related factors affect skin sensitivity preferences, and cultural considerations influence acceptance of visible sleep aids. These regional and demographic insights help manufacturers develop targeted product lines that better serve diverse customer needs.