Designing NasalStrips for Snoring Relief Without Medical Claims

Sleep disruption affects millions of people worldwide, with snoring being one of the most common culprits. The development of effective nasal strips has become a growing focus for manufacturers seeking to provide non-medical solutions for better breathing during sleep. These innovative adhesive devices work by gently lifting and opening nasal passages, allowing for improved airflow without making any medical claims or promises of treating specific conditions.

The design process for nasal strips requires careful consideration of materials, adhesion properties, and user comfort. Engineers and product developers must balance effectiveness with skin safety, ensuring that the strips can be worn throughout the night without causing irritation or discomfort. Modern nasal strips incorporate advanced materials science to create products that are both functional and user-friendly.

Understanding the biomechanics of nasal breathing is essential for creating effective nasal strips. The human nose contains complex structures that can become congested or restricted due to various factors including sleeping position, environmental conditions, or natural anatomical variations. By addressing these mechanical aspects through thoughtful design, manufacturers can create products that enhance the natural breathing process.

Material Selection and Engineering Principles

Adhesive Technology for Skin-Safe Applications

The foundation of effective nasal strips lies in selecting appropriate adhesive materials that provide strong hold without causing skin damage. Medical-grade adhesives are typically preferred for their hypoallergenic properties and ability to maintain adhesion throughout the night. These specialized materials must be tested extensively to ensure they meet safety standards while providing the necessary lifting force to open nasal passages.

Advanced adhesive formulations incorporate breathable properties that allow air circulation beneath the strip, preventing moisture buildup that could compromise adhesion. The adhesive layer must also be designed to release cleanly upon removal, minimizing discomfort and reducing the risk of skin irritation. Manufacturers often conduct extensive dermatological testing to validate the safety profile of their adhesive systems.

Temperature stability is another crucial factor in adhesive selection for nasal strips. Body heat and varying room temperatures can affect adhesive performance, so formulations must maintain consistent properties across a range of environmental conditions. This ensures reliable performance regardless of seasonal variations or individual body temperature differences.

Structural Design for Optimal Lift and Comfort

The physical structure of nasal strips involves careful engineering to achieve the right balance of flexibility and lifting power. The backing material typically consists of a flexible polymer that provides spring-like tension when applied to the curved surface of the nose. This tension creates the lifting action that helps open nasal passages without requiring excessive force that might cause discomfort.

Shape optimization involves extensive research into nasal anatomy to ensure the strips conform properly to various nose shapes and sizes. Computer-aided design tools help engineers model the stress distribution and lifting forces to optimize performance across diverse user populations. The goal is to create a one-size-fits-most solution that works effectively for the broadest possible range of users.

Ventilation features are often incorporated into the design to enhance comfort during extended wear. Small perforations or channel designs can help manage moisture and improve breathability without compromising structural integrity. These features contribute to overall user satisfaction and encourage consistent use of the product.

Manufacturing Processes and Quality Control

Precision Assembly and Coating Techniques

Manufacturing high-quality nasal strips requires precision equipment capable of applying adhesive coatings uniformly across the backing material. Roll-to-roll coating processes are commonly employed to ensure consistent adhesive thickness and coverage. Quality control systems monitor coating weight and uniformity throughout the production process to maintain product consistency.

Die-cutting operations must be precisely calibrated to create strips with smooth, rounded edges that enhance comfort and reduce the likelihood of premature lifting at the corners. Sharp or rough edges can create discomfort and compromise the effectiveness of the product. Automated inspection systems verify dimensional accuracy and edge quality for every produced unit.

Packaging considerations play a vital role in maintaining product integrity from manufacturing to end use. Individual packaging protects the adhesive surface and maintains sterility while providing convenient dispensing for consumers. Packaging materials must be selected to prevent adhesive degradation while ensuring easy opening without damaging the product.

Testing and Validation Protocols

Comprehensive testing protocols ensure that nasal strips meet performance and safety requirements before reaching consumers. Adhesion strength testing measures the force required to remove strips from standardized surfaces, ensuring adequate hold without excessive removal force. These tests simulate various conditions including moisture exposure and temperature variations.

Biocompatibility testing validates that materials are safe for prolonged skin contact. These studies typically include patch testing, sensitization studies, and cytotoxicity evaluations performed according to recognized international standards. The testing process helps manufacturers demonstrate the safety profile of their products and identify any potential issues before market introduction.

Performance validation involves real-world testing with volunteer subjects to assess comfort, effectiveness, and user acceptance. These studies provide valuable feedback on design improvements and help optimize the user experience. Data collected during validation testing also supports marketing claims about product performance and user satisfaction.

User Experience and Design Optimization

Ergonomic Considerations for All-Night Wear

Designing nasal strips for extended wear requires careful attention to ergonomic factors that affect user comfort throughout the night. The contour of the strip must match the natural curve of the nose while providing consistent lifting force as the user moves during sleep. Edge design is particularly important, as poorly designed edges can create pressure points that cause discomfort or premature lifting.

Sleep movement patterns influence design considerations, as users may change positions multiple times during the night. The strips must maintain adhesion and lifting effectiveness despite these movements while remaining comfortable in various sleeping positions. Flexibility testing simulates these conditions to ensure reliable performance throughout typical sleep cycles.

Skin sensitivity considerations are paramount in design optimization, as prolonged contact can potentially cause irritation in sensitive individuals. Material selection focuses on hypoallergenic properties, while design features such as breathable zones help minimize moisture buildup that could exacerbate sensitivity issues. Regular user feedback helps manufacturers refine their designs for maximum comfort.

Application and Removal Ease

User-friendly application is essential for product acceptance and consistent use. Clear visual indicators help users position nasal strips correctly on their first attempt, reducing waste and improving effectiveness. Design features such as alignment guides or color-coding can simplify the application process, making it intuitive even in low-light conditions typical of bedtime routines.

Removal mechanisms should minimize discomfort while ensuring complete adhesive removal without residue. Some designs incorporate removal tabs or other features that facilitate easy removal in the morning. The goal is to make both application and removal quick and painless, encouraging regular use as part of a healthy sleep routine.

Instructions and packaging play important roles in user education, helping consumers understand proper application techniques and expected performance characteristics. Clear, illustrated instructions can significantly improve user success rates and overall satisfaction with the product. Packaging design should also protect the product while providing easy access and clear information about proper use.

Innovation Trends in Nasal Strip Technology

Advanced Materials and Magnetic Enhancement

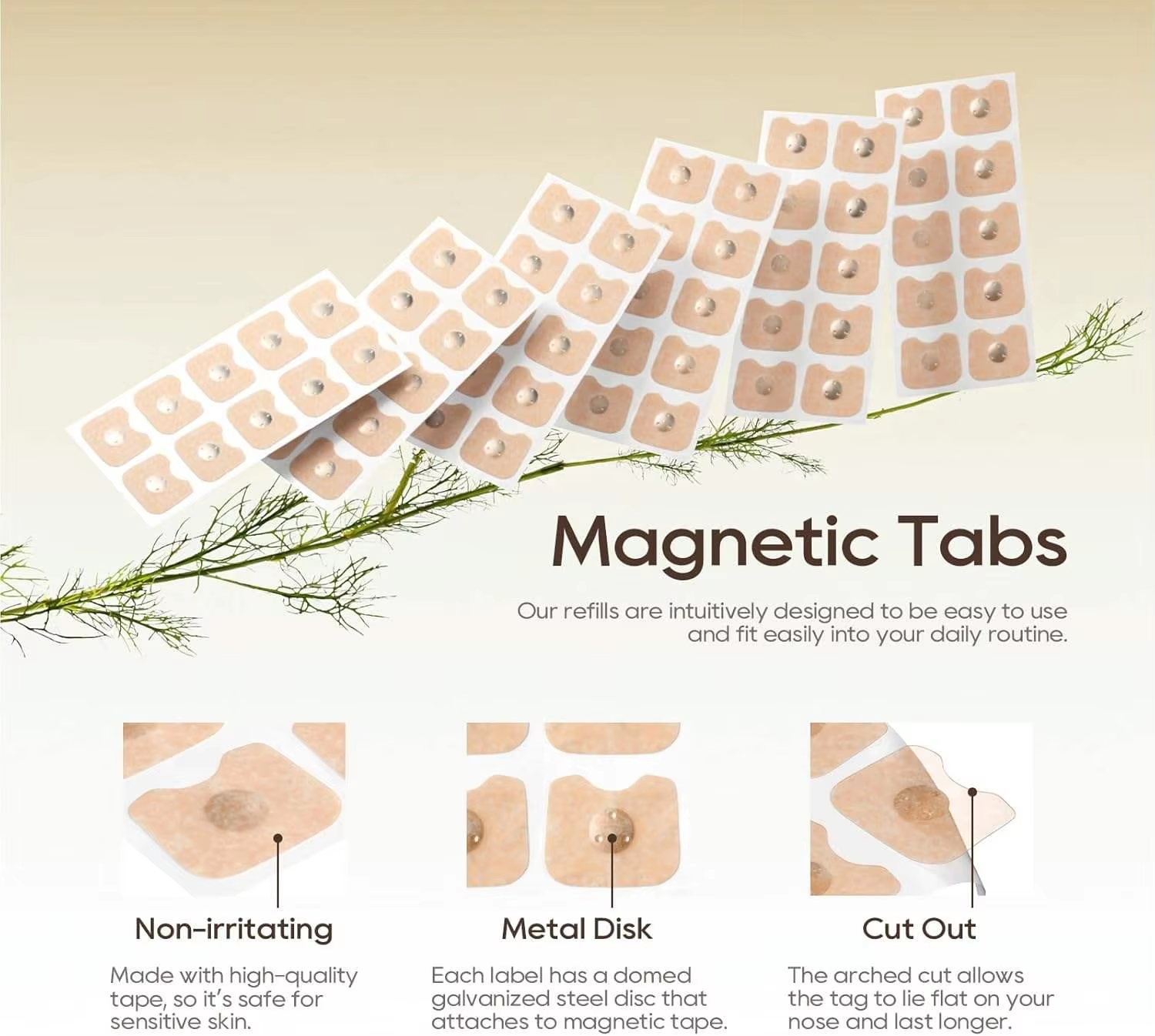

Recent innovations in nasal strips include the integration of magnetic elements that provide additional lifting force without relying solely on adhesive tension. Magnetic nasal strips incorporate small, safe magnets that work together to create a lifting effect that can be more consistent than traditional spring-tension designs. These magnetic systems are engineered to be safe for extended skin contact while providing enhanced performance.

Smart materials that respond to body temperature or moisture levels represent another frontier in nasal strip development. These materials can adjust their properties based on environmental conditions, potentially improving comfort and effectiveness throughout the night. Research into shape-memory polymers and other responsive materials may lead to next-generation nasal strips with adaptive properties.

Antimicrobial coatings and materials are being explored to enhance hygiene and safety during extended wear. These treatments can help prevent bacterial growth and reduce the risk of skin irritation, particularly important for users who may have sensitive skin or who use nasal strips regularly over extended periods.

Customization and Personalization Features

Advances in manufacturing technology are enabling more personalized nasal strips that can be customized for individual nasal anatomy. 3D scanning and printing technologies may eventually allow for custom-fitted strips that provide optimal performance for each user's unique nasal structure. These developments could significantly improve effectiveness while maintaining the convenience of a ready-to-use product.

Size variations and adjustable designs are becoming more common, allowing users to select products that best match their specific needs. Some manufacturers offer multiple sizes or adjustable features that can accommodate a wider range of nasal shapes and sizes. This customization approach helps ensure that more users can benefit from improved nasal airflow during sleep.

Digital integration possibilities are being explored, including strips that could potentially interface with sleep tracking devices or smartphone applications. While still in early development stages, these concepts could provide users with feedback about their breathing patterns and sleep quality, helping them optimize their use of nasal strips for better rest.

Market Considerations and Consumer Needs

Understanding Target Demographics

The market for nasal strips encompasses diverse demographics with varying needs and preferences. Athletes seeking improved breathing during physical activity represent one important segment, requiring strips that can withstand perspiration and maintain adhesion during vigorous movement. These users often prioritize performance and durability over other features such as discrete appearance.

Sleep-focused consumers constitute the largest market segment, seeking products that improve breathing comfort throughout the night without causing discomfort or skin irritation. This group typically values consistent performance, easy application and removal, and long-term skin safety. Understanding these priorities helps manufacturers develop products that meet real-world user needs.

Occasional users who may use nasal strips during illness or allergy seasons have different requirements than regular users. These consumers often prioritize immediate effectiveness and affordability over long-term comfort features. Products targeting this segment may emphasize quick relief and convenient packaging for intermittent use.

Regulatory Compliance and Safety Standards

Regulatory requirements for nasal strips vary by market but generally focus on material safety and manufacturing quality. Products must typically comply with standards for skin-contact materials and demonstrate that they do not cause harm during normal use. Manufacturers must maintain detailed documentation of testing results and quality control procedures to ensure compliance with applicable regulations.

Labeling requirements mandate clear communication about proper use, potential side effects, and contraindications. Manufacturers must be careful to avoid making medical claims while still providing sufficient information for safe and effective use. This balance requires careful consideration of language and claims substantiation to ensure regulatory compliance.

International market considerations add complexity to regulatory compliance, as different regions may have varying requirements for materials, testing, and documentation. Manufacturers seeking global distribution must ensure their products meet the most stringent applicable standards while maintaining cost-effectiveness across different markets.

Environmental and Sustainability Considerations

Eco-Friendly Material Options

Growing environmental awareness is driving demand for more sustainable nasal strips that minimize environmental impact without compromising performance. Biodegradable backing materials derived from renewable sources offer potential alternatives to traditional petroleum-based polymers. These materials must still meet performance requirements for flexibility, strength, and compatibility with adhesive systems.

Recyclable packaging solutions are being developed to reduce waste associated with individual product packaging. While maintaining product integrity and hygiene requirements, manufacturers are exploring packaging designs that use less material or incorporate recyclable components. These efforts help address consumer concerns about environmental impact while maintaining product quality.

Water-based adhesive formulations may offer environmental advantages over solvent-based systems while potentially reducing manufacturing emissions. However, these alternatives must demonstrate equivalent performance characteristics including adhesion strength, removal properties, and shelf stability. The development of environmentally preferred adhesives represents an ongoing area of research and development.

Lifecycle Assessment and Waste Reduction

Comprehensive lifecycle assessments help manufacturers understand the total environmental impact of their nasal strips from raw material extraction through disposal. These assessments identify opportunities for improvement in material selection, manufacturing processes, packaging design, and end-of-life disposal. The insights gained help guide sustainable product development decisions.

Waste reduction strategies during manufacturing include optimizing cutting patterns to minimize material waste and developing recycling programs for production scraps. Some manufacturers are exploring closed-loop systems where waste materials can be reprocessed and incorporated into new products, reducing overall environmental impact while potentially lowering costs.

Consumer education about proper disposal helps ensure that used nasal strips are handled appropriately at end-of-life. While individual strips represent relatively small amounts of waste, the cumulative impact of widespread use makes proper disposal education important for overall environmental stewardship. Clear disposal instructions can help consumers make environmentally responsible choices.

FAQ

How do nasal strips work to improve breathing during sleep

Nasal strips work by using spring-like tension to gently lift and open the nasal passages from the outside. The flexible backing material creates an upward pulling force when applied to the bridge of the nose, which helps expand the nasal opening and allows for increased airflow. This mechanical action can help reduce breathing resistance without making any medical claims about treating specific conditions.

What materials are typically used in modern nasal strip construction

Modern nasal strips typically use medical-grade adhesives for skin contact, combined with flexible polymer backing materials that provide spring tension. Common backing materials include polyethylene or other flexible plastics that maintain their shape while allowing comfortable movement. The adhesive systems are formulated to be hypoallergenic and provide strong hold while allowing easy removal without skin damage.

Are there any skin safety considerations when using nasal strips regularly

Regular use of nasal strips is generally considered safe when products are designed with appropriate materials and used according to instructions. However, individuals with sensitive skin should monitor for any signs of irritation and may want to alternate application sites slightly to prevent prolonged pressure on the same area. If irritation occurs, discontinuing use and consulting with a healthcare professional is recommended.

How long can nasal strips be worn continuously

Most nasal strips are designed for single-night use, typically worn for 8-12 hours during sleep. The adhesive properties and comfort features are optimized for this duration, after which the strips should be removed and discarded. Attempting to wear strips for longer periods may result in reduced effectiveness, increased risk of skin irritation, or adhesive failure that could compromise performance.