Product Design Considerations for Athletic NasalStrips

Athletic performance depends on numerous factors, with proper breathing being one of the most critical yet often overlooked elements. Athletic nasal strips have emerged as a revolutionary solution for athletes seeking to optimize their respiratory efficiency during training and competition. These specialized devices are engineered to mechanically open nasal passages, allowing for increased airflow and enhanced oxygen delivery to working muscles. The design and functionality of athletic nasal strips represent a convergence of biomechanical engineering, material science, and sports medicine principles that demand careful consideration during the product development process.

The physiological benefits of improved nasal breathing extend far beyond simple comfort, impacting cardiovascular efficiency, oxygen saturation levels, and overall athletic endurance. Modern athletic nasal strips must address the unique challenges faced by competitive athletes, including extreme physical exertion, perspiration, temperature variations, and the need for consistent performance across extended periods. Understanding these requirements is essential for manufacturers developing products that can withstand the rigorous demands of professional and amateur athletic activities while delivering measurable performance improvements.

Material Engineering and Adhesive Technology

Advanced Polymer Selection for Athletic Applications

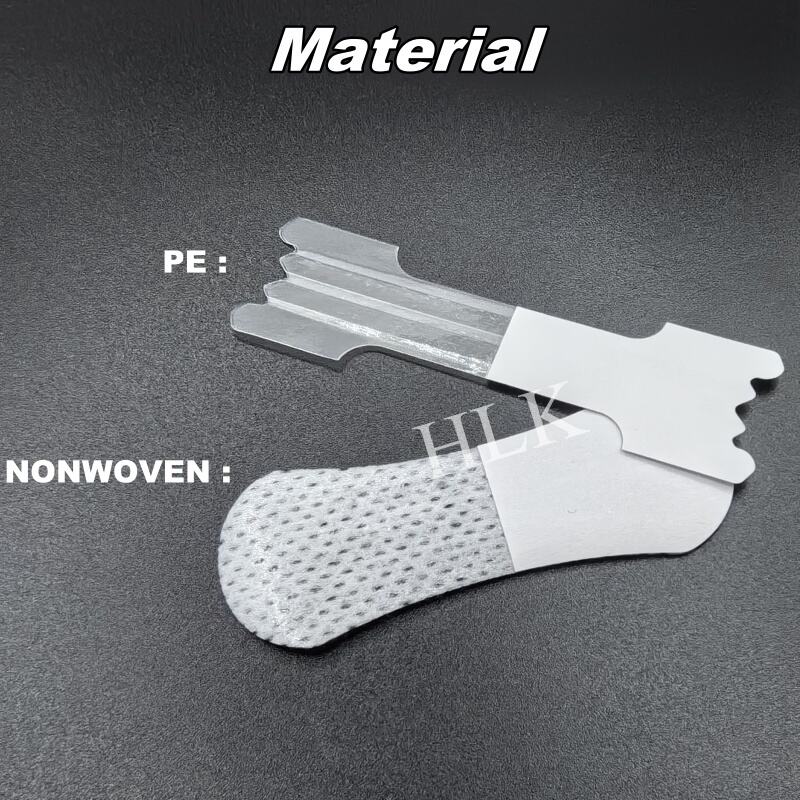

The foundation of effective athletic nasal strips lies in the careful selection of polymer materials that can withstand the mechanical stresses associated with athletic performance. High-performance thermoplastic elastomers provide the necessary flexibility and spring-back characteristics required for consistent nasal dilation throughout extended periods of physical activity. These materials must demonstrate exceptional fatigue resistance, maintaining their elastic properties even after repeated flexing cycles that occur during breathing under exercise conditions.

Modern athletic nasal strips incorporate advanced polymer blends that exhibit superior temperature stability, ensuring consistent performance across varying environmental conditions. The polymer matrix must also demonstrate resistance to degradation from exposure to UV radiation, moisture, and common skincare products that athletes may use. Material engineers focus on developing formulations that balance flexibility with structural integrity, creating products that conform to diverse nasal anatomies while maintaining sufficient lifting force to achieve meaningful airway expansion.

Adhesive Performance Under Extreme Conditions

The adhesive system represents perhaps the most critical component in athletic nasal strip design, as it must maintain secure attachment despite exposure to perspiration, humidity, and dynamic facial movements. Medical-grade pressure-sensitive adhesives are formulated specifically for skin contact applications, incorporating biocompatible compounds that minimize the risk of allergic reactions or skin irritation during extended wear periods. These adhesive systems must demonstrate immediate tack properties for easy application while providing sustained adhesion throughout athletic activities.

Sweat resistance represents a primary design challenge for adhesive engineers, requiring the development of hydrophobic formulations that maintain bonding strength even when exposed to significant moisture levels. Advanced adhesive technologies incorporate microstructured surfaces and moisture-wicking properties that channel perspiration away from the bonding interface, preventing adhesive failure during critical performance moments. The removal characteristics must also be carefully balanced, allowing for comfortable removal without causing skin damage or excessive discomfort.

Biomechanical Design Principles

Nasal Anatomy Considerations

Effective design of athletic nasal strips requires comprehensive understanding of nasal anatomy and the biomechanical forces involved in natural breathing processes. The nasal valve area, located at the narrowest portion of the nasal cavity, represents the primary target for mechanical intervention through external nasal dilation devices. Engineering teams must consider the wide variations in nasal anatomy across different populations, ensuring that their designs accommodate diverse nose shapes, sizes, and structural characteristics.

The spring constant of athletic nasal strips must be carefully calibrated to provide sufficient lifting force without causing discomfort or tissue damage. Biomechanical modeling helps engineers determine optimal force distribution patterns that maximize nasal dilation while minimizing pressure points on sensitive nasal tissues. The curvature profiles of the strips must align with natural nasal contours, ensuring uniform force application and preventing stress concentrations that could lead to discomfort or reduced effectiveness.

Ergonomic Optimization for Athletic Performance

Athletic nasal strips must integrate seamlessly with the dynamic facial movements associated with various sports activities, from the intense facial expressions of weightlifting to the rhythmic breathing patterns of endurance running. Ergonomic design principles guide the development of strip profiles that maintain effectiveness regardless of facial muscle contractions or changes in facial geometry during physical exertion. The strips must also accommodate the use of protective equipment such as helmets, masks, or eyewear commonly used in athletic applications.

Weight distribution becomes a critical factor in high-performance athletic applications, where even minimal additional mass can impact aerodynamics or comfort during extended use. Engineers focus on minimizing material usage while maintaining structural integrity, often employing advanced manufacturing techniques such as precision die-cutting or laser processing to achieve optimal weight-to-performance ratios. The center of gravity and moment of inertia must be carefully considered to prevent the strips from shifting or creating unwanted torque effects during rapid head movements.

Performance Validation and Testing Protocols

Airflow Measurement Methodologies

Quantifying the performance benefits of athletic nasal strips requires sophisticated measurement techniques that can accurately assess changes in nasal airflow under realistic exercise conditions. Rhinomanometry provides objective measurements of nasal resistance and airflow rates, allowing engineers to validate design improvements and compare performance across different strip configurations. These measurements must be conducted under various simulated exercise intensities to ensure that performance benefits translate to real-world athletic applications.

Computational fluid dynamics modeling has become an essential tool for optimizing athletic nasal strip designs, enabling engineers to visualize airflow patterns and identify areas for improvement before physical prototyping. Advanced simulation techniques can model the complex interactions between nasal anatomy, strip mechanics, and airflow dynamics, providing insights that guide design refinements. These analytical approaches help reduce development time and costs while ensuring that final products deliver measurable performance improvements for athletic users.

Clinical Validation and User Testing

Comprehensive clinical testing protocols ensure that athletic nasal strips deliver the promised performance benefits while maintaining safety and comfort standards. These studies typically involve controlled exercise testing with objective physiological measurements, including oxygen saturation levels, heart rate variability, and perceived exertion ratings. The testing must encompass diverse athletic populations and activity types to validate performance claims across broad user demographics.

Long-term wear testing evaluates the durability and skin compatibility of athletic nasal strips under realistic usage conditions. These protocols assess adhesive performance, material degradation, and user comfort over extended periods, ensuring that products maintain effectiveness throughout typical usage scenarios. Accelerated aging tests simulate long-term environmental exposure, helping manufacturers establish appropriate shelf life and storage recommendations for their products.

Manufacturing and Quality Control Considerations

Precision Manufacturing Techniques

The manufacturing of athletic nasal strips requires precise control over material properties, dimensional tolerances, and adhesive application parameters. Advanced die-cutting technologies enable the production of strips with consistent geometry and edge quality, ensuring uniform performance characteristics across production batches. Automated adhesive coating systems provide precise control over adhesive thickness and distribution, critical factors in achieving consistent bonding performance and user comfort.

Quality control systems must monitor multiple parameters throughout the manufacturing process, including material tensile properties, adhesive peel strength, and dimensional accuracy. Statistical process control methods help identify trends and variations that could impact product performance, enabling proactive adjustments to maintain consistent quality standards. Clean room manufacturing environments ensure that products meet medical device standards for contamination control and sterility requirements.

Packaging and Sterilization Requirements

Packaging design for athletic nasal strips must protect product integrity while providing convenient access for athletes in various environments. Individual packaging prevents contamination and maintains adhesive properties, while tear-resistant materials ensure reliable opening even with wet or gloved hands. The packaging must also provide clear instructions and application guidance to ensure proper usage and maximize performance benefits.

Sterilization protocols ensure that athletic nasal strips meet safety standards for skin contact applications while preserving material properties and adhesive performance. Gamma radiation and ethylene oxide sterilization methods are commonly employed, requiring careful validation to confirm that sterilization processes do not compromise product functionality or cause material degradation that could affect performance or safety characteristics.

Innovation Trends and Future Developments

Smart Technology Integration

Emerging trends in athletic nasal strip design include the integration of smart technologies that can monitor breathing patterns and provide real-time feedback to athletes and coaches. Miniaturized sensors embedded within the strips can measure airflow rates, breathing frequency, and other physiological parameters, creating opportunities for data-driven training optimization and performance analysis. These technologies require careful integration to maintain the lightweight and unobtrusive characteristics essential for athletic applications.

Wireless connectivity enables athletic nasal strips to integrate with broader fitness monitoring ecosystems, providing comprehensive respiratory data alongside traditional metrics such as heart rate and movement patterns. Advanced algorithms can analyze breathing efficiency and provide personalized recommendations for training adjustments or technique modifications. The development of biocompatible electronics and flexible circuit technologies makes these innovations increasingly feasible for commercial athletic nasal strip applications.

Personalized Design Approaches

Future developments in athletic nasal strips focus on personalization technologies that can customize strip characteristics to individual nasal anatomy and performance requirements. Three-dimensional scanning and modeling technologies enable the creation of custom-fitted strips that optimize performance for specific users, potentially delivering superior results compared to standard one-size-fits-all approaches. These personalized solutions represent the next evolution in athletic nasal strip technology.

Advanced manufacturing techniques such as 3D printing and programmable material systems open new possibilities for creating athletic nasal strips with variable stiffness profiles or adaptive characteristics that respond to changing conditions during use. These innovations could enable strips that automatically adjust their lifting force based on exercise intensity or breathing patterns, optimizing performance throughout extended athletic activities while maintaining user comfort and safety.

FAQ

How do athletic nasal strips differ from standard nasal strips

Athletic nasal strips are specifically engineered for the demanding conditions of sports and exercise activities. They feature enhanced adhesive systems that resist sweat and moisture, stronger polymer construction to withstand dynamic facial movements, and optimized spring forces to maintain effectiveness during increased respiratory demands. The materials used in athletic nasal strips typically demonstrate superior durability and temperature stability compared to standard versions designed for static applications.

What factors determine the effectiveness of athletic nasal strips

The effectiveness of athletic nasal strips depends on proper fit to individual nasal anatomy, adequate lifting force to open nasal passages, secure adhesion throughout activity, and material properties that maintain consistency under exercise conditions. Individual factors such as nasal valve anatomy, breathing patterns, and activity intensity also influence performance outcomes. Proper application technique and strip selection based on nasal size and shape are critical for optimal results.

How long can athletic nasal strips be worn during exercise

Most athletic nasal strips are designed for single-use applications lasting 8-12 hours, though the practical wear time during intense exercise may be shorter depending on perspiration levels and activity intensity. The adhesive systems are formulated to maintain secure attachment throughout typical training sessions or competitive events. Extended wear beyond recommended timeframes may result in reduced adhesive performance or potential skin irritation from prolonged adhesive contact.

Are there any safety considerations when using athletic nasal strips

Athletic nasal strips are generally safe when used according to manufacturer guidelines, but users should be aware of potential skin sensitivities to adhesive materials. Individuals with compromised nasal tissue, active skin conditions, or known adhesive allergies should consult healthcare professionals before use. Proper removal technique is important to prevent skin damage, and users should discontinue use if irritation, discomfort, or adverse reactions occur during or after application.