Manufacturing Challenges of Hydrogel Mouth Tape

The production of hydrogel mouth tape represents a complex intersection of advanced materials science, precision manufacturing, and strict quality control protocols. As sleep health awareness continues to grow globally, manufacturers face increasing pressure to deliver products that not only meet consumer expectations but also comply with stringent regulatory standards. The unique properties of hydrogel materials present both opportunities and significant manufacturing challenges that require specialized expertise and sophisticated production capabilities.

Manufacturing hydrogel mouth tape involves navigating numerous technical hurdles, from material formulation and adhesive consistency to packaging integrity and shelf-life stability. Each stage of the production process requires meticulous attention to detail, as even minor variations can significantly impact product performance and user safety. Understanding these challenges is crucial for manufacturers seeking to establish themselves in this rapidly expanding market segment.

Material Science Complexities in Hydrogel Production

Polymer Matrix Formulation Challenges

The foundation of effective hydrogel mouth tape lies in achieving the optimal polymer matrix composition. Manufacturers must carefully balance multiple hydrophilic polymers to create a structure that maintains adequate moisture retention while providing appropriate adhesive properties. The selection of base polymers such as polyvinyl alcohol, polyethylene glycol, or sodium polyacrylate requires extensive testing to determine the ideal molecular weight distributions and crosslinking densities.

Temperature sensitivity during the polymerization process presents another significant challenge. Hydrogel formation requires precise thermal control to ensure uniform crosslinking without degrading the polymer chains. Variations in temperature can lead to inconsistent gel strength, affecting both the tape's structural integrity and its ability to maintain consistent adhesion throughout the night. Manufacturing facilities must invest in sophisticated temperature monitoring and control systems to maintain product consistency.

The incorporation of biocompatible additives further complicates the formulation process. Moisturizing agents, antimicrobial compounds, and skin-conditioning ingredients must be integrated without disrupting the hydrogel matrix structure. Each additive can potentially alter the crosslinking behavior, water retention capacity, or mechanical properties of the final product, requiring extensive compatibility testing and formulation optimization.

Water Content Optimization

Achieving the optimal water content in hydrogel mouth tape represents a critical balancing act that significantly impacts manufacturing success. Too much water content can lead to premature degradation, reduced shelf life, and potential microbial growth, while insufficient hydration results in poor adhesion and user discomfort. Manufacturers must establish precise water activity levels that maintain product efficacy while ensuring long-term stability.

The drying process requires sophisticated environmental controls to achieve uniform water distribution throughout the hydrogel matrix. Controlled atmosphere chambers with precise humidity, temperature, and airflow management are essential to prevent surface skin formation or internal moisture gradients. These environmental variations can create weak points in the final product, leading to premature failure or inconsistent performance characteristics.

Quality control testing for water content involves multiple analytical methods, including Karl Fischer titration, thermogravimetric analysis, and dynamic vapor sorption measurements. Each testing protocol requires specialized equipment and trained personnel, adding significant overhead costs to the manufacturing process while ensuring product consistency and regulatory compliance.

Adhesive Performance Engineering

Skin-Safe Adhesion Technology

Developing adhesive formulations for hydrogel mouth tape that provide reliable overnight adherence without causing skin irritation or damage upon removal presents unique engineering challenges. The adhesive must maintain consistent bonding strength across varying skin types, moisture levels, and facial hair conditions while remaining gentle enough for sensitive perioral skin. This requires sophisticated polymer chemistry expertise and extensive biocompatibility testing protocols.

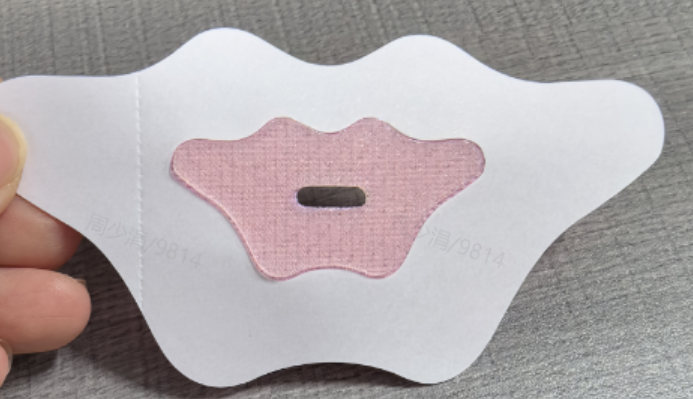

The adhesive layer must be engineered to work synergistically with the hydrogel base, creating a cohesive system that maintains integrity throughout the wearing period. Traditional pressure-sensitive adhesives often prove incompatible with hydrogel matrices, requiring the development of specialized formulations that can bond effectively with both the gel substrate and human skin. This typically involves custom acrylic or silicone-based systems with specific molecular architectures.

Manufacturing consistency in adhesive application presents significant technical challenges. The adhesive must be applied in uniform thickness across the entire contact surface, requiring precision coating equipment and real-time monitoring systems. Variations in coating thickness can create pressure points or areas of inadequate adhesion, compromising product performance and user safety.

Environmental Stability Considerations

Hydrogel mouth tape adhesive systems must maintain performance characteristics across a wide range of environmental conditions, from humid summer nights to dry winter environments. The adhesive formulation must resist degradation from temperature fluctuations, humidity variations, and extended storage periods. This requires comprehensive accelerated aging studies and environmental stress testing protocols.

Packaging interactions with the adhesive system create additional manufacturing complexities. The release liner material must provide adequate protection without transferring contaminants or altering the adhesive properties. Manufacturers must carefully select liner materials and conduct extensive compatibility studies to ensure product integrity throughout the distribution chain.

The challenge of maintaining adhesive tackiness without compromising removability requires precise control over crosslinking density and plasticizer content. Over-crosslinked adhesives may provide excellent initial tack but become difficult to remove, while under-crosslinked formulations may fail to maintain adequate adhesion throughout the wearing period. This balance requires sophisticated rheological analysis and mechanical testing protocols.

Quality Control and Testing Protocols

Biocompatibility Validation

Ensuring the biocompatibility of hydrogel mouth tape requires comprehensive testing protocols that go beyond basic skin irritation studies. Manufacturers must conduct cytotoxicity assays, sensitization testing, and long-term wear studies to validate product safety across diverse user populations. These studies require specialized laboratory facilities, trained personnel, and significant time investments before products can reach market.

The complexity of hydrogel mouth tape formulations necessitates testing individual components as well as the complete product system. Each raw material must undergo toxicological evaluation, while the finished product requires assessment of potential leachables and extractables that could cause adverse reactions. This multi-tier testing approach significantly extends development timelines and increases regulatory compliance costs.

Establishing appropriate acceptance criteria for biocompatibility testing requires close collaboration with regulatory agencies and medical professionals. The perioral application site presents unique challenges compared to traditional adhesive products, requiring specialized test protocols that accurately simulate real-world usage conditions while maintaining statistical validity.

Performance Consistency Metrics

Manufacturing hydrogel mouth tape requires establishment of robust performance metrics that ensure consistent product quality across production batches. Key parameters include adhesive strength measurements, moisture retention testing, dimensional stability analysis, and wear time validation. Each metric requires specialized testing equipment and standardized protocols to generate reproducible results.

Statistical process control becomes particularly challenging with hydrogel mouth tape due to the inherent variability in biological materials and environmental sensitivity of the product. Manufacturers must implement sophisticated data collection systems and advanced statistical analysis tools to identify trends and maintain process capability indices within acceptable ranges.

The development of accelerated testing protocols for predicting long-term product performance represents a significant technical challenge. Traditional accelerated aging methods may not accurately reflect the complex degradation mechanisms of hydrogel systems, requiring the development of custom protocols that provide meaningful predictions of real-world performance.

Production Scaling and Economic Considerations

Manufacturing Infrastructure Requirements

Scaling hydrogel mouth tape production from laboratory prototypes to commercial manufacturing volumes requires substantial investments in specialized equipment and facility infrastructure. Clean room environments with controlled temperature, humidity, and particulate levels are essential to maintain product quality and prevent contamination. The initial capital investment for appropriate manufacturing facilities can represent a significant barrier to market entry.

The unique properties of hydrogel materials require custom processing equipment designed specifically for handling moisture-sensitive formulations. Traditional converting equipment used for standard adhesive tapes often proves inadequate for hydrogel applications, necessitating custom machinery development or significant modifications to existing systems. This specialized equipment typically comes with higher maintenance requirements and limited supplier options.

Workforce training represents another significant challenge in hydrogel mouth tape manufacturing. Production personnel require specialized knowledge of polymer chemistry, sterile processing techniques, and quality control procedures specific to medical device manufacturing. The limited availability of experienced personnel in this specialized field can create staffing challenges and increase labor costs.

Supply Chain Complexity

The specialized raw materials required for hydrogel mouth tape production often come from limited supplier bases, creating potential supply chain vulnerabilities. High-purity polymers, pharmaceutical-grade additives, and specialized packaging materials may have long lead times and minimum order quantities that complicate production planning and inventory management.

Quality qualification of raw material suppliers requires extensive auditing and validation processes to ensure consistent material properties and regulatory compliance. Each supplier must demonstrate adequate quality systems, traceability protocols, and change control procedures. The time and resources required for supplier qualification can significantly extend product development timelines.

Managing the cold chain requirements for certain hydrogel components adds complexity and cost to the supply chain. Temperature-sensitive materials may require specialized shipping and storage conditions, increasing logistics costs and creating potential quality risks if temperature excursions occur during transportation or warehousing.

Regulatory Compliance Challenges

Medical Device Classification

The regulatory classification of hydrogel mouth tape varies significantly across global markets, creating compliance challenges for manufacturers seeking international distribution. In some jurisdictions, these products may be classified as medical devices requiring extensive clinical data and regulatory submissions, while others may treat them as cosmetic or wellness products with less stringent requirements.

Navigating the medical device regulatory pathway requires substantial documentation including design controls, risk analysis, clinical evaluation, and quality system implementation. The cost and complexity of regulatory compliance can represent a significant portion of total product development investment, particularly for smaller manufacturers with limited regulatory expertise.

Maintaining regulatory compliance across multiple markets requires ongoing monitoring of regulatory changes and timely implementation of any required modifications to manufacturing processes or quality systems. The dynamic nature of medical device regulations creates ongoing compliance costs and potential market access risks.

Clinical Evidence Requirements

Depending on regulatory classification, hydrogel mouth tape manufacturers may need to generate clinical evidence supporting product safety and efficacy claims. Clinical studies for sleep-related products present unique challenges in study design, patient recruitment, and outcome measurement. The subjective nature of sleep quality assessments complicates the development of objective endpoints.

The cost of clinical studies can be substantial, particularly for randomized controlled trials required to support efficacy claims. Study costs include protocol development, regulatory submissions, clinical site management, data collection and analysis, and statistical reporting. These investments may not be feasible for all manufacturers, particularly those targeting niche market segments.

Post-market surveillance requirements add ongoing compliance obligations including adverse event reporting, periodic safety updates, and clinical follow-up studies. These requirements necessitate robust quality systems and ongoing resource allocation for regulatory maintenance activities.

Future Manufacturing Innovations

Advanced Materials Development

The future of hydrogel mouth tape manufacturing lies in the development of next-generation materials with enhanced performance characteristics and simplified processing requirements. Research into smart hydrogels that respond to physiological changes, biodegradable formulations for improved environmental sustainability, and multi-functional systems incorporating active ingredients represents the cutting edge of product development.

Nanotechnology applications in hydrogel mouth tape formulations offer potential improvements in mechanical properties, antimicrobial efficacy, and controlled release capabilities. However, the incorporation of nanomaterials introduces additional regulatory considerations and manufacturing complexity that must be carefully managed to ensure product safety and compliance.

Advances in polymer synthesis techniques, including controlled polymerization methods and novel crosslinking chemistries, may enable the development of hydrogel systems with more predictable properties and improved manufacturing consistency. These technological advances could reduce production variability and enable more cost-effective manufacturing processes.

Process Automation and Quality Assurance

The implementation of advanced process automation and real-time quality monitoring systems represents a significant opportunity for improving hydrogel mouth tape manufacturing efficiency and consistency. Inline monitoring technologies, including spectroscopic analysis and machine vision systems, can provide immediate feedback on product quality and enable rapid process adjustments.

Artificial intelligence and machine learning applications in manufacturing process control offer the potential for predictive quality management and automated optimization of processing parameters. These technologies could reduce waste, improve yield, and enhance overall product consistency while reducing the need for extensive post-production testing.

The integration of digital manufacturing technologies, including digital twins and advanced process modeling, can accelerate product development timelines and reduce the cost of process optimization. These tools enable virtual testing of manufacturing parameters and rapid evaluation of design modifications without the need for extensive physical prototyping.

FAQ

What are the primary technical challenges in hydrogel mouth tape manufacturing?

The primary technical challenges include achieving optimal polymer matrix formulation, maintaining consistent water content throughout production, developing skin-safe adhesive systems that provide reliable overnight adherence, and implementing comprehensive quality control protocols. Each challenge requires specialized expertise in materials science, precision manufacturing equipment, and extensive testing capabilities to ensure product safety and efficacy.

How does regulatory compliance impact hydrogel mouth tape manufacturing costs?

Regulatory compliance significantly impacts manufacturing costs through required biocompatibility testing, clinical studies, quality system implementation, and ongoing post-market surveillance activities. Depending on the regulatory classification, manufacturers may need to invest substantial resources in regulatory submissions, clinical evidence generation, and maintaining compliance across multiple global markets, which can represent a significant portion of total product development investment.

What specialized equipment is required for hydrogel mouth tape production?

Specialized equipment requirements include controlled atmosphere chambers for precise environmental control during gel formation and drying, custom coating systems for uniform adhesive application, clean room facilities to prevent contamination, and sophisticated analytical instruments for quality control testing. Traditional tape converting equipment often requires significant modifications or complete replacement to handle the unique properties of hydrogel materials effectively.

How do supply chain complexities affect hydrogel mouth tape manufacturing?

Supply chain complexities arise from the limited availability of specialized raw materials, stringent quality requirements for pharmaceutical-grade components, cold chain management needs for temperature-sensitive materials, and extensive supplier qualification processes. These factors can create longer lead times, higher inventory costs, increased quality risks, and potential supply disruptions that must be carefully managed through robust supply chain planning and risk mitigation strategies.